What We're Learning from Investing in B2U - Part 2

A Phoenix Rising in Lancaster's Sun-Drenched Desert

This week I’m excited to welcome My Next Electric’s Investor-In-Residence, Peter Christensen, for the latest in a series on our emerging investment thesis, Batteries Included. To catch up on the discussion, check out our previous posts:

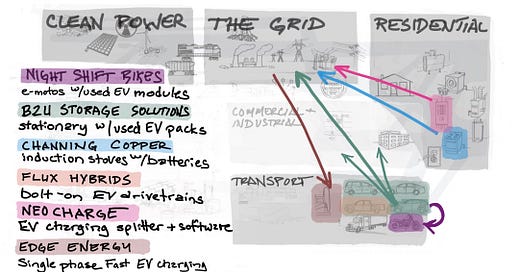

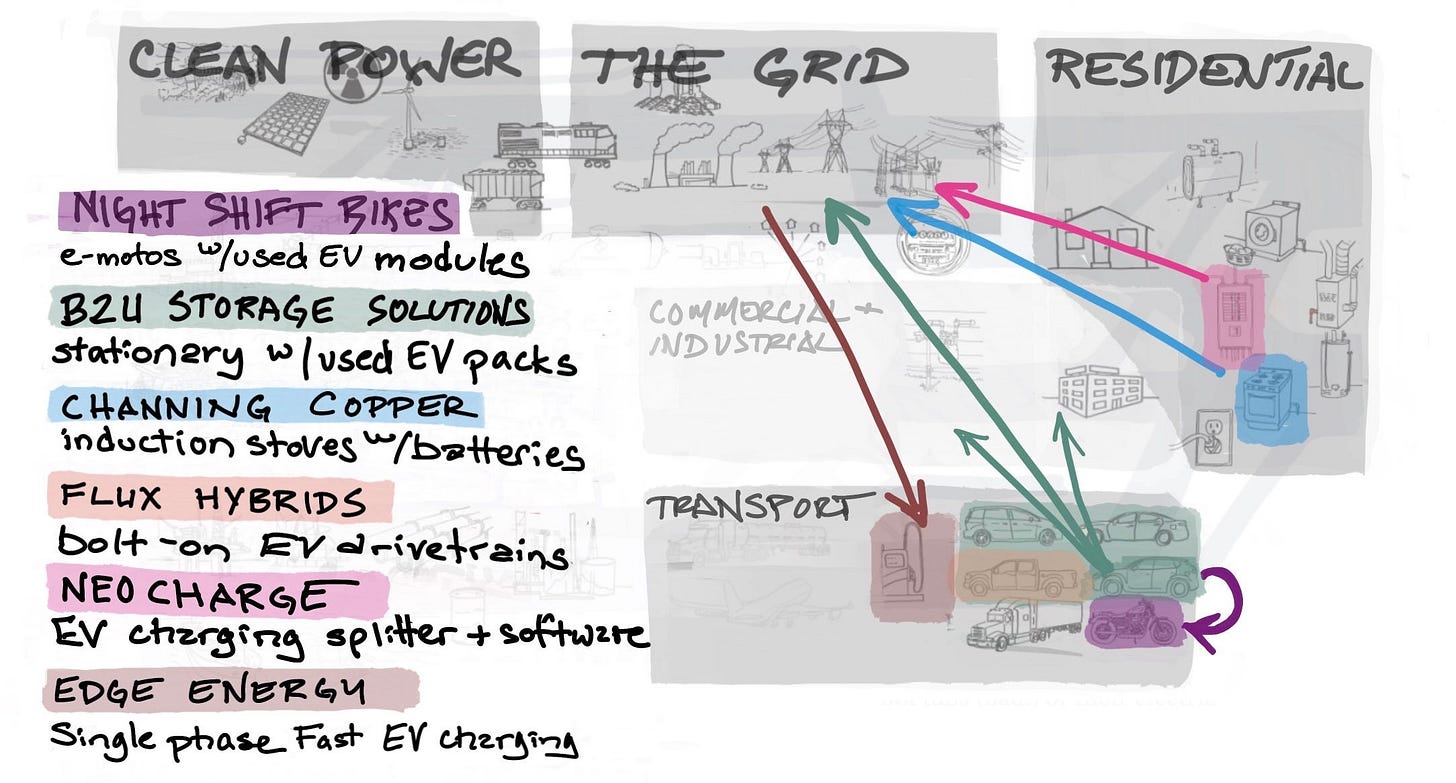

Post 1 on creating our investing map,

Post 2 on how building electric motorcycles informs our investing,

Post 3 on B2U Storage Solutions (1 of 2), and

Post 4 on Channing Street Copper Company’s induction stoves.

This post picks up where Matt left off on B2U’s origin story and digs into where B2U is today and how it shapes our emerging investment thesis.

Solar power innovation in the Mojave Desert

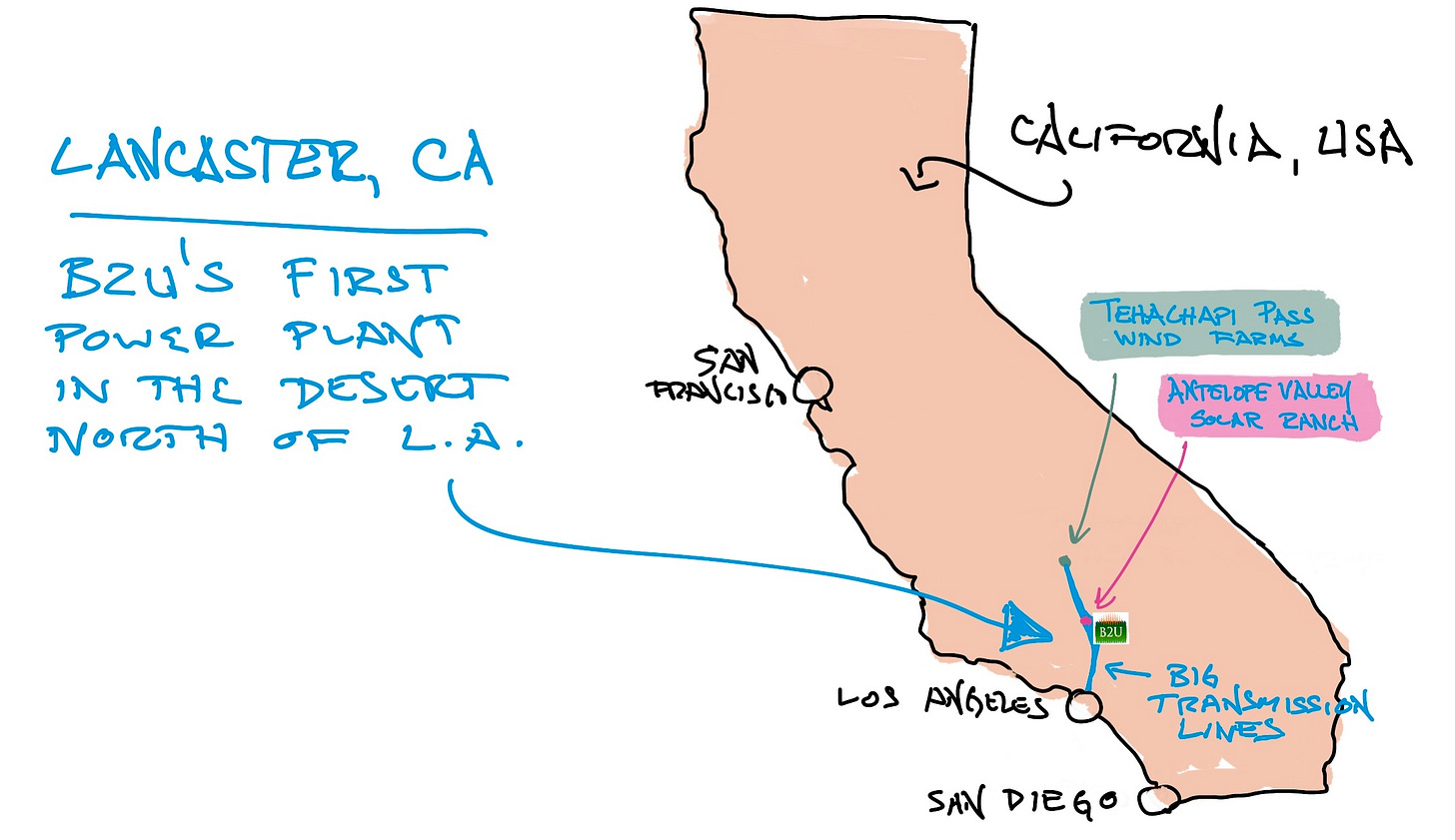

Just an hour's drive north of Los Angeles is Lancaster, California, where the sun shines for more than 300 days a year.

It’s a hotspot for solar generation projects like Antelope Valley Solar Ranch. Owned by Exelon and backed by a $646 million Department of Energy loan guarantee, this ranch full of solar panels is a 242-MW behemoth that reached full commercial operation in 2014. Many more like it have come online here since.

Just up the road that same desert sun provided a crucible for a different kind of solar power generation.

The eSolar Sierra SunTower was a bold, $65M experiment that aimed to capitalize on Lancaster's sunny disposition. The concentrated solar-thermal generation plant aimed thousands of mirrors at a central tower where all that sunlight could superheat water for use in steam generators.

eSolar forecasted an annual production of 4,270 MWh. Data from Southern California Edison revealed that between August 1, 2010, and July 31, 2011, the facility generated less that 540 MWh — 12% of the original estimate. eSolar found the project too expensive to operate more than a few days a month, and Sierra SunTower was soon shuttered and scrapped for parts.

B2U connects a different kind of resource to the grid

It's often said that innovation thrives on the heels of failure.

A few years later, B2U took up residence on the same site as the ill-fated Sierra SunTower; Co-Founder Freeman Hall saw no reason to let that nice grid connection go unused. Rather than seeing the site as a monument to a failed past, he reimagined it as a launchpad for a promising future in energy storage.

B2U built a small solar field in a corner of the sprawling eSolar site and used it to charge up a few hundred battery modules taken out of used Nissan Leaf electric cars.

It worked; what would become the largest 2nd-life energy storage plant in the US was underway.

While touring their Lancaster facility, it was clear to me that the team at B2U is keenly aware of the burgeoning trends in battery energy storage and retired Electric Vehicle (EV) batteries. Over the next decade, the U.S. is expected to see a 42X increase in battery storage capacity and a 13X growth in the stock of retired EV batteries. B2U is not just a spectator to these mega trends; it's a leader.

After that small experiment with laptop computer-sized battery modules, the company’s patented technology now takes retired, full-size battery packs from EVs and repurposes them for large-scale storage projects. It uniquely addresses the limitations often associated with 2nd life batteries, offering a robust solution that unlocks value long after they’re too tired to work inside vehicles.

This is crucial, especially when you consider that McKinsey projects the total addressable market for the reuse of EV batteries to be around 200 GWh annually, a $10 billion opportunity by 2030.

B2U's iterative design approach has paved the way for pack reuse, presenting significant cost advantages over module-based second-life solutions. This is part of what makes their patented technology so compelling: it eliminates the hefty repurposing costs usually associated with second-life batteries and automates the processes involved.

This automation is key for scalability, particularly when considering the expected $300 billion in CapEx investment required to meet skyrocketing demand for storage capacity.

B2U isn't just about repurposing old batteries; it's about creating an ecosystem where every stage of a battery's life is optimized for maximum utility and minimum waste. By safely reusing batteries in large-scale, second-life storage projects, B2U is not only capitalizing on immediate market opportunities; it’s laying the groundwork for a more sustainable economy.

Gunpei Yokoi’s Lateral Innovation with Withered Technology

B2U is a prime example of lateral innovation with withered technology, a core concept of our Batteries Included investment thesis.

Coined by Gunpei Yokoi, a prolific Japanese inventor known for his contributions to Nintendo, including the Game Boy, lateral innovation with withered technology refers to using mature or even outdated technology in new, groundbreaking ways. Rather than pushing the envelope with cutting-edge, costly tech, Yokoi believed in the creative repurposing of existing, proven technology. The Nintendo Game Boy didn't have the best graphics or a color screen when it was launched, but its affordability, battery life, and gameplay gave it an edge in the market.

Instead of seeking new inventions to solve a challenge, lateral innovation focuses on getting existing tools into new markets. By laterally repositioning older batteries built for vehicles as stationary storage, B2U has created a business model that gets profitable faster.

B2U: The Future Awaits

Just as Yokoi's Game Boy became an enduring icon by repurposing existing technologies in a novel way, B2U is paving the way for a new era of effective solutions in the energy sector.

In a world where the speed of technological advancements often outpaces our ability to adapt or even understand them fully, the lessons from B2U and Gunpei Yokoi remind us that sometimes, the most impactful innovations come not from the creation of new technologies, but from the creative application of what already exists.

About the Author

Peter Christensen is a deep-tech entrepreneur and investor in residence for My Next Electric. Peter holds a PhD in Chemistry and is the co-founder FLO Materials and Loamist. He is an Activate Fellow, and has been using his scientific background to build companies that address the complex challenges of climate and the circular economy. Peter is based in San Diego where he lives with his wife Kelsey, daughter Goldie, and their dog Lou.